Grain Journal Article: Extron Monitoring System Detects Hot Spot in Idaho Ground Pile

Rudy deWit estimates that his facility’s Extron Grain Management System saved his company $100,000 worth of wheat stored in a temporary ground pile, when it detected an unsuspected hot spot.

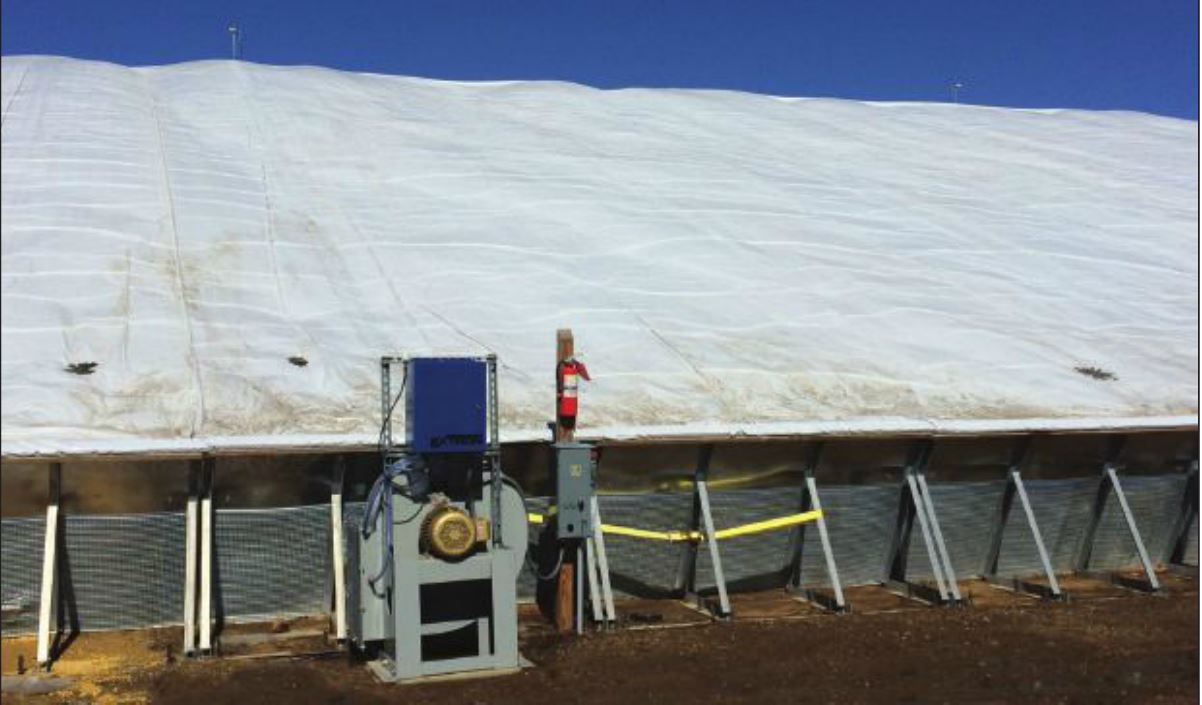

The 1-million-bushel pile is located at Thresher Artisan Wheat’s 2.5 million-bushel grain elevator in Rockford, ID (208-785-4460). Thresher is a division of Agspring, LLC, which purchased the elevator from General Mills in April 2014.

“This is high desert country,” comments deWit, vie president of Idaho operations, “so wheat usually goes into storage at low moisture, 9% to 10 1/2%. Our biggest challenge is insect control.

Shortly after Thresher acquired the Rockford elevator, the company installed an Extron Ground Pile Management System, distributed in the United States by The Lakeland Companies, Plymouth, MN (763-543-9437).

While the oval-shaped, 150-foot-x-500-foot bunker at Rockford is technically “temporary” storage, deWit, vice president of Idaho operations, notes that the pile is set up for ‘reasonably long-term storage.” Wheat harvest in southeast Idaho takes place in mid-to-late July, and the hot spot event in question occurred in mid-March 2015, eight months after harvest,

“We had a perforated plastic aeration pipe that was improperly assembled,” he says. “As a result, the pipe filled with wheat, which blocked the movement of air. This showed up on our Grain Management System as a section of the pile with grain temperatures that were increasing steadily over the course of several weeks. The temperature climbed about 15 degrees in total.”

At this point, deWit instructed workers to begin picking up that section of wheat immediately and moving it to upright storage or to loadout saving it from potentiality spoilage.

System Benefits

The Extron Ground Pile Management System offered a number of features Thresher managers found especially suitable to the situation at Rockford:

- Wireless sensor probes monitor both temperatures and carbon dioxide (CO2). At up to 30 feet in length, the probes were particularly well suited for the Rockford pile, which stacks up to 38 feet tall.

- Data from the probes is sent wirelessly to an Extron secure server and is viewable via website. No special software or operating system is needed to access the data, just a computer or smart device with Internet access. The user can view current conditions, analyze trends, set up alarm notifications, and add additional users.

- The system also includes aeration fan control system with three modes of operation – cool down, maintain, and warmup. It controls the fan motors wirelessly using variable frequency drive technology. The system also monitors rpm, watts, current (amperage), local and NOAA wind speeds, exhaust temperatures, and differential pressure. By managing shrink loss and saving energy costs by up to 60%, Lakeland claims less than a two-year return on investment.

- The CO2 monitoring package mounts on existing fan housing for an easy retrofit. It communicates parts-per-million readings and exhaust temperatures wirelessly to the system controller, as well as ambient temperatures, differential pressure, and (optional) humidity.

Accoriding to deWit, the Rockford facility uses all of the modular components of the Extron system. “We’re extremely pleased with it,” he says, noting that the company plans to utilize the system at other locations in the new future.

– Ed Zdrojewski, Editor